Choosing the Right Industrial Rubber Hose: Key Factors to Consider

Apr 08,2025

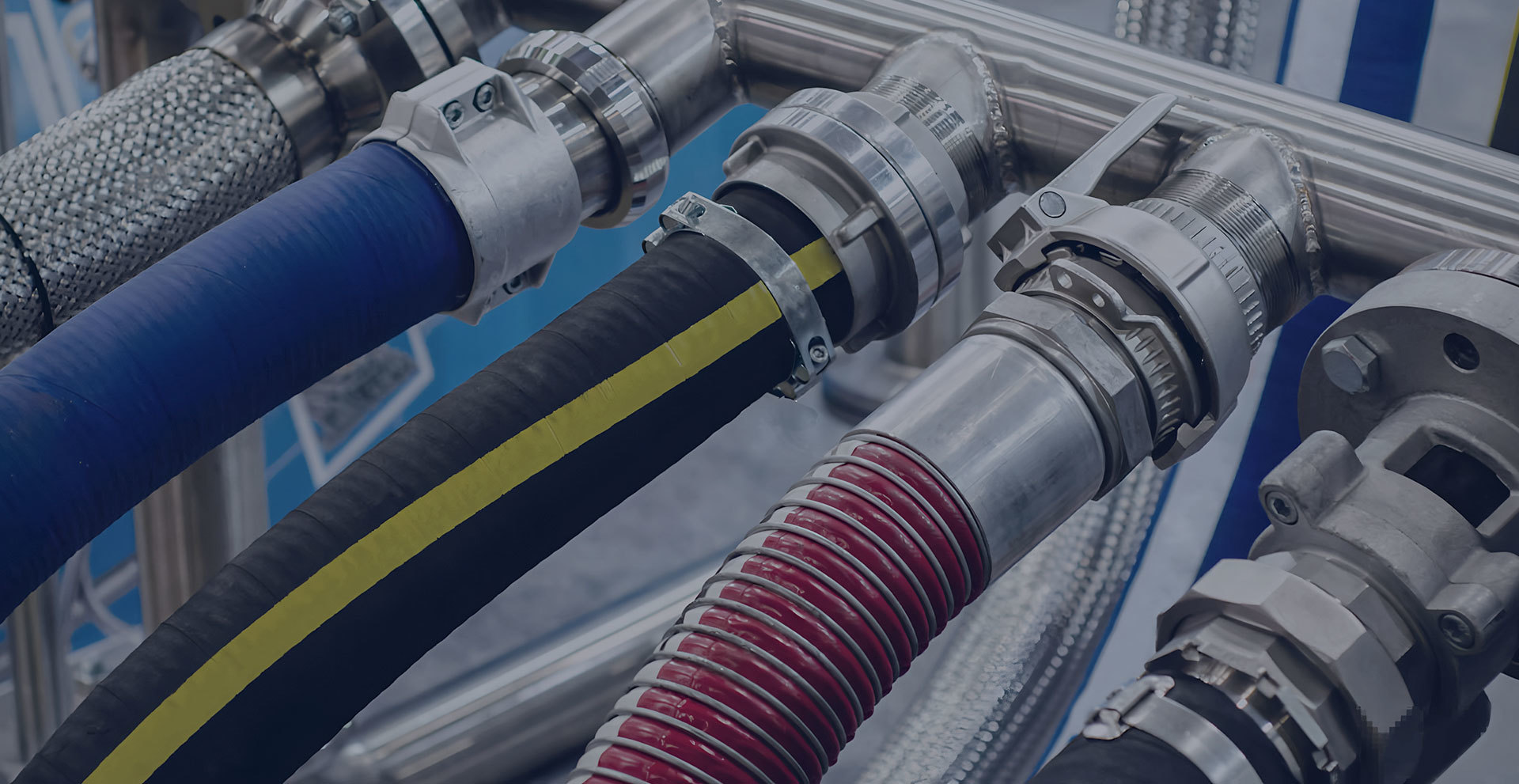

In the world of industrial applications, the selection of the right rubber hose is a critical decision that can significantly impact operational efficiency, safety, and overall performance. With a myriad of options available in the market, it is essential to understand the key factors that influence the selection process.

In the world of industrial applications, the selection of the right rubber hose is a critical decision that can significantly impact operational efficiency, safety, and overall performance. With a myriad of options available in the market, it is essential to understand the key factors that influence the selection process. This article aims to provide insights into the most important considerations when choosing an industrial rubber hose.

1. Understanding the Application

The first step in selecting the appropriate rubber hose is to thoroughly understand the application it will be used for. Different industries have varying requirements based on the nature of the materials being transported, the operating environment, and the specific tasks at hand.Factors such as temperature, pressure, and the type of fluid being transported are crucial. High-pressure applications will require hoses that can withstand greater stress, while high-temperature applications may necessitate hoses that are specifically designed to endure extreme conditions. Moreover, the compatibility of the hose material with the fluid being conveyed is paramount to prevent degradation or chemical reactions.

2. Hose Construction and Material

Industrial rubber hoses can be made from various materials, including natural rubber, synthetic rubber, and reinforced composites. Each material has its own set of properties, such as flexibility, abrasion resistance, and chemical compatibility.

3. Size and Diameter

Selecting the correct size and diameter of the hose is essential to ensure optimal flow rates and prevent issues such as kinking or collapsing. The inner diameter of the hose must match the specifications of the equipment it will connect to, as using a hose that is too small can restrict flow and lead to pressure build-up. Conversely, a hose that is too large may result in inefficient flow and increased friction loss.

It is also important to consider the length of the hose. While longer hoses provide flexibility in terms of reach, they can also lead to pressure drops and increased wear and tear. Therefore, it is advisable to choose a hose length that meets operational needs without unnecessary excess.

4. Pressure Ratings

Every industrial rubber hose comes with a specified pressure rating, which indicates the maximum pressure it can safely handle. It is critical to select a hose with a pressure rating that exceeds the maximum pressure of the application to ensure safety and reliability. Operating a hose beyond its pressure rating can lead to catastrophic failures, resulting in equipment damage and potential hazards to personnel.

Conclusion

Choosing the right industrial rubber hose is a decision that requires careful consideration of multiple factors. By understanding the application, evaluating hose construction and materials, and considering size, pressure ratings, temperature tolerance, environmental conditions, and compliance standards, you can make an informed decision that enhances operational efficiency and safety. Investing the time to select the appropriate hose will ultimately lead to improved performance and reduced maintenance costs in the long run.

Key words: