A guide to Selecting Drilling Hoses for your project

Apr 26,2025

Drilling hose also called Oilfield drilling hose, rotary drilling hose, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs.

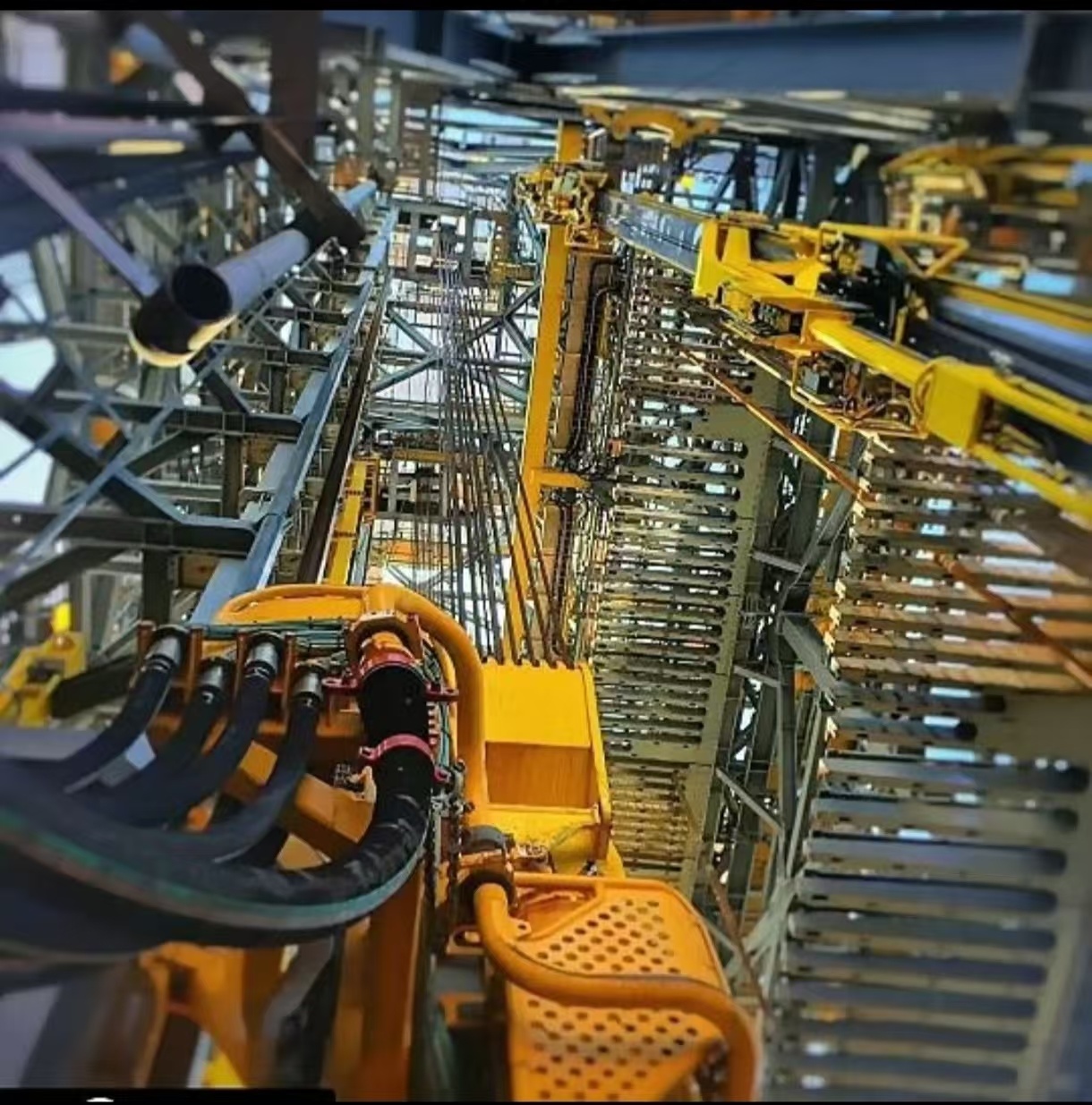

Oilfield drilling hoses have found their wide application in the extraction of minerals such as oil & gas drilling. With the help of the drill pipe, a drilling mud is injected into the well at a very high pressure, most often technical water, hydrogel solution or clay-based solutions. The drill hose is also used between oil tankers and drilling wells in the sea.Drilling hoses can be used on stationary and mobile drilling rigs, for drilling wells in the sea.

The drilling rotary hose is suitable for flexible connection between the top of the drilling riser and the swivel which can move vertically. It resists corrosion of hydrogen sulfide and can deliver water, oil, mud high‐pressure media.

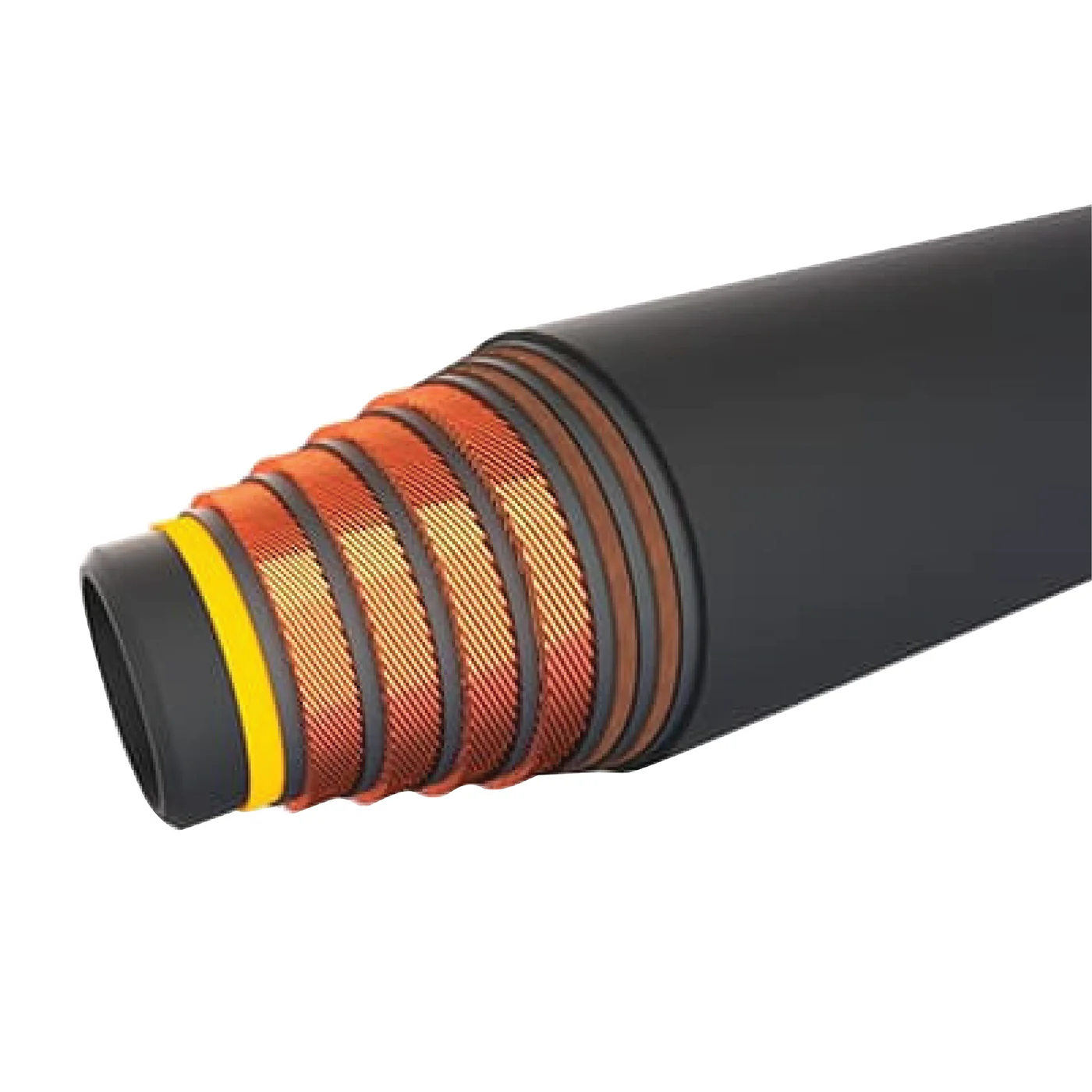

The details of rotary drilling hose:

Structure: it is composed of three parts: tube, reinforcement and cover.

Tube: high quality synthetic rubber, mainly NBR, which is resistant to abrasion, corrosion and oils.

Reinforcement: 2-8 layers of high tensile and high strength spiraled steel wire, making the hose work well in high pressure working conditions.

Cover: high quality synthetic rubber, mainly chloroprene rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, aging and sunlight.

Working temperature: -30 °C to +82 °C.

The hose has longer service life as a result.

Note: Rotary drilling hose can be divided into five kinds according to the working pressure: grade A, grade B, grade C, grade D and grade E.

Application of Rotary Drilling Hose:

It is mainly used for conveying water-based or oil-based mud and other fluids.

It is often used for oil fields, cement repairing, geological exploration and water conveyance for coal excavation.

Conclusion:

A rotary vibrator and drilling hose certified to API 7K standards and offering a wide range of connections provide indispensable support in the demanding environments of oil and gas drilling operations. Engineered to withstand extreme pressure, vibration, and abrasion, these hoses ensure reliable performance and enhanced safety throughout drilling processes. The API 7K certification guarantees compliance with rigorous industry standards, assuring operators of the hose's quality, durability, and reliability. With a diverse selection of connections available, including threaded, flanged, and hammer unions, these hoses offer versatility and compatibility with various drilling equipment and systems, facilitating seamless integration into drilling operations. Additionally, their robust construction and advanced materials minimise wear and tear, reducing the risk of downtime and maintenance costs. Overall, a rotary vibrator and drilling hose certified to API 7K standards and featuring a wide range of connections deliver dependable performance, contributing to increased efficiency and productivity in drilling operations while prioritising safety.

Key words: