How to choose the right Drilling Rotary Table safety table mat?

Apr 25,2025

This article introduces the characteristics, material selection and purchasing suggestions of the drill platform safety Mats

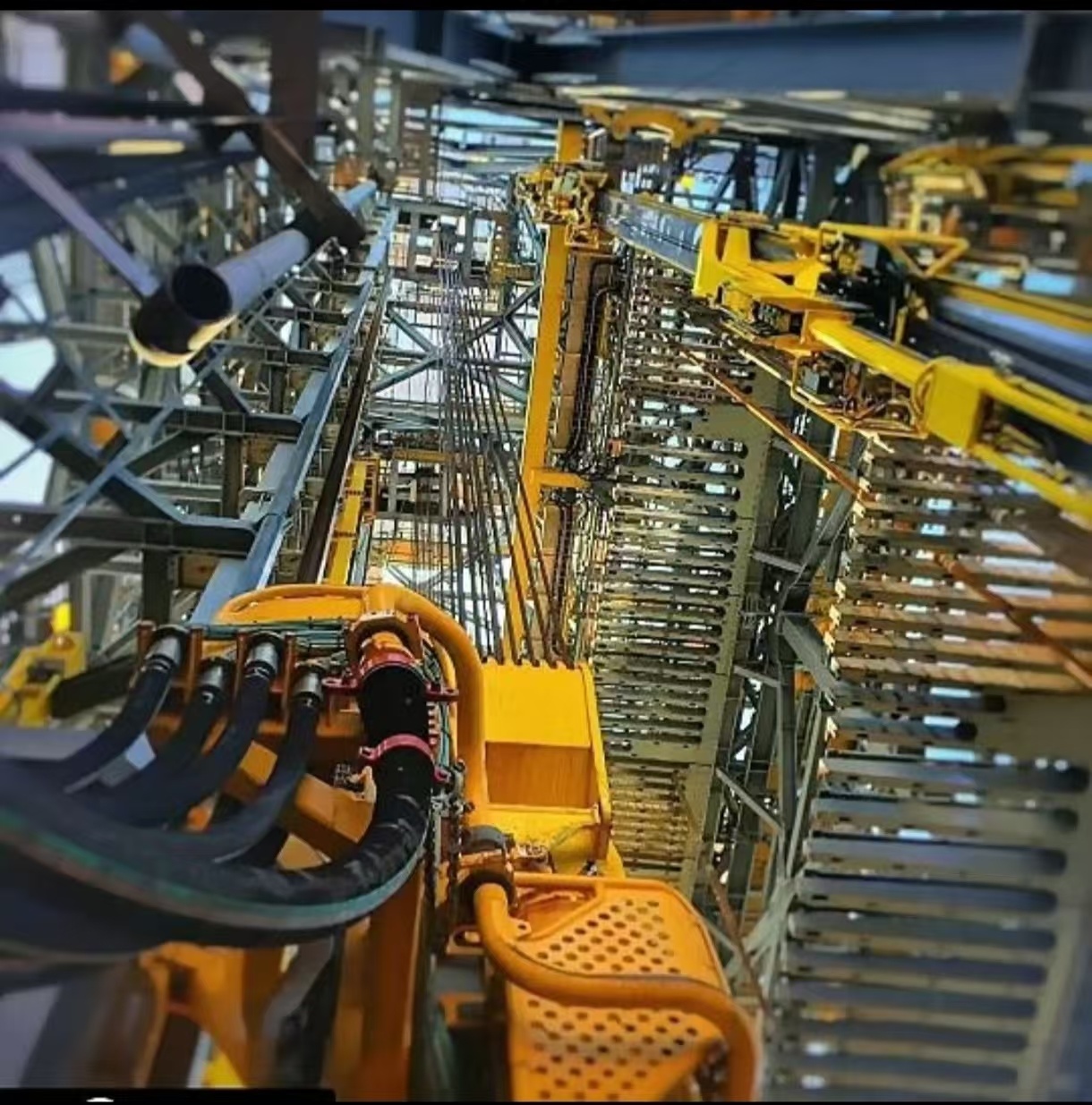

Importance of Rig Safety Table Mats

Rig anti-slip safety table mats are a crucial part in ensuring the safety and reducing fatigue of workers in the oil and gas industry. These mats not only provide a non-slip surface but also offer insulation against electric shocks, protecting employees from potential hazards. Additionally, rig safety table mats act as a protective barrier against spills and chemical exposure, reducing the risk of accidents and injuries in high-risk work environments.

Composed of Rig Safety Table Mats

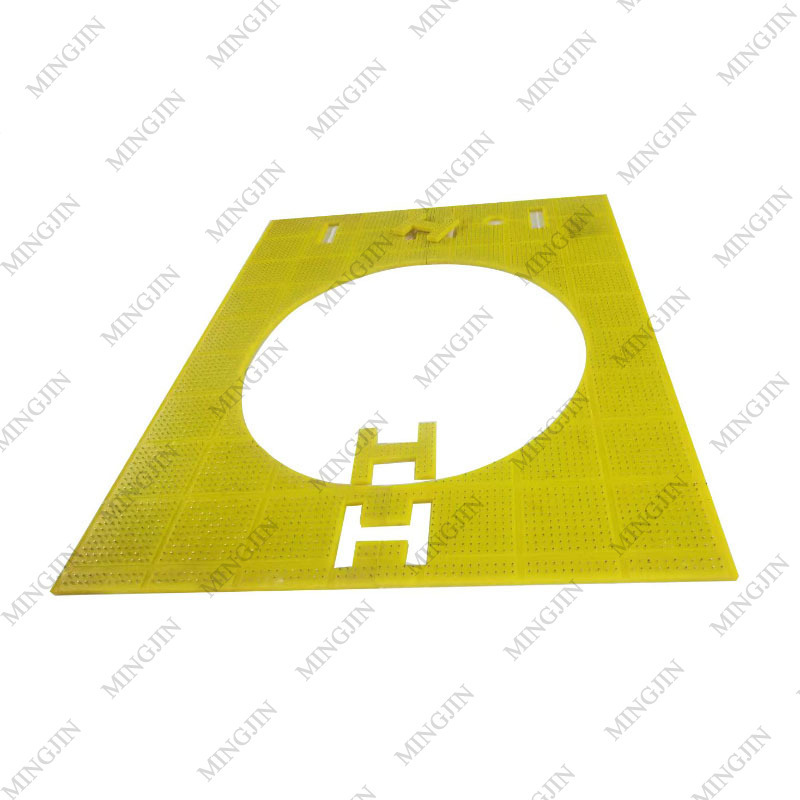

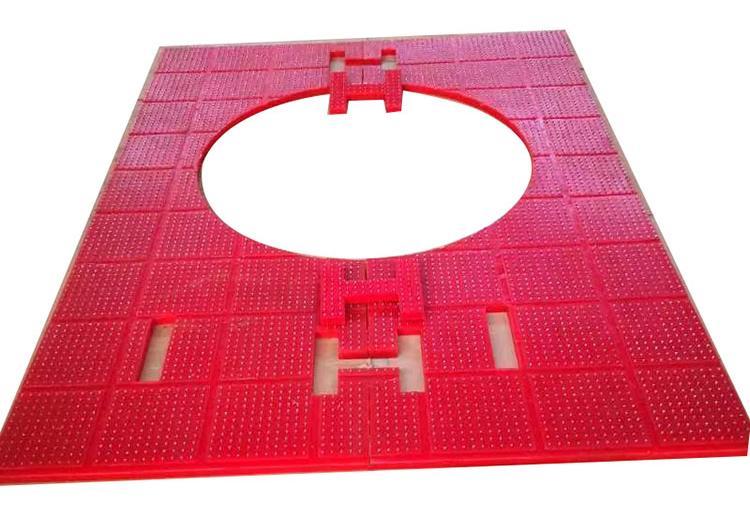

Material considerations play a crucial role in ensuring safety and durability. The drilling platform safety mats is composed of high-purity polyurethane raw materials and neatly arranged nails.

Polyurethane rubber features high strength, good elasticity, oil resistance, solvent resistance, excellent low-temperature performance and good anti-aging ability. The surface features multiple vertical and horizontal drainage channels, which are enclosed in a square area. Through the drainage channels on the upper surface of the main bodymats, there is a combination of protruding rubber particles and metal nails embedded in the protruding surface of the main body part. The protruding rubber particles and metal rivets are regularly staggered. The height of the highly protruding rubber particles and the metal rivets protruding from the upper surface of the mat not only effectively prevents slipping but also ensures that the operator does not feel uncomfortable when standing on the mat.

By comprehensively evaluating these material considerations, safety table mats can be selected, which not only enhance workplace safety but also provide long-term value and reliability.

Size and Thickness Guidelines

Factors such as heavy machinery use, frequency of foot traffic, and potential spillage should all be taken into account when determining the most suitable specifications for rig safety table mats. By customizing these aspects according to specific work demands, companies can ensure optimal safety measures are in place to protect their workforce from preventable accidents.

The size of the mat should be large enough to cover the entire work surface, providing ample space for workers to move around and perform tasks without restriction. Additionally, the thickness of the mat plays a critical role in impact absorption and fatigue reduction. A thicker mat can provide better cushioning and support for standing workers, reducing the risk of strain or injury during long shifts.

Conclusion: Making the Right Choice

Investing in high quality anti-slip rig safety mats not only enhances the safety of workers but also saves on maintenance costs over time. By choosing durable mats that can withstand heavy loads, extreme temperatures, and corrosive substances, companies can avoid frequent replacements and repairs. This not only contributes to cost savings but also ensures uninterrupted operations by reducing downtime associated with mat maintenance or replacement. In essence, prioritizing durability in rig safety mats means investing in the long-term efficiency and integrity of oil rig operations.

Key words: