Hammer Union: Convenient and Efficient Pipeline Connectors in the Petroleum Industry

Apr 02,2025

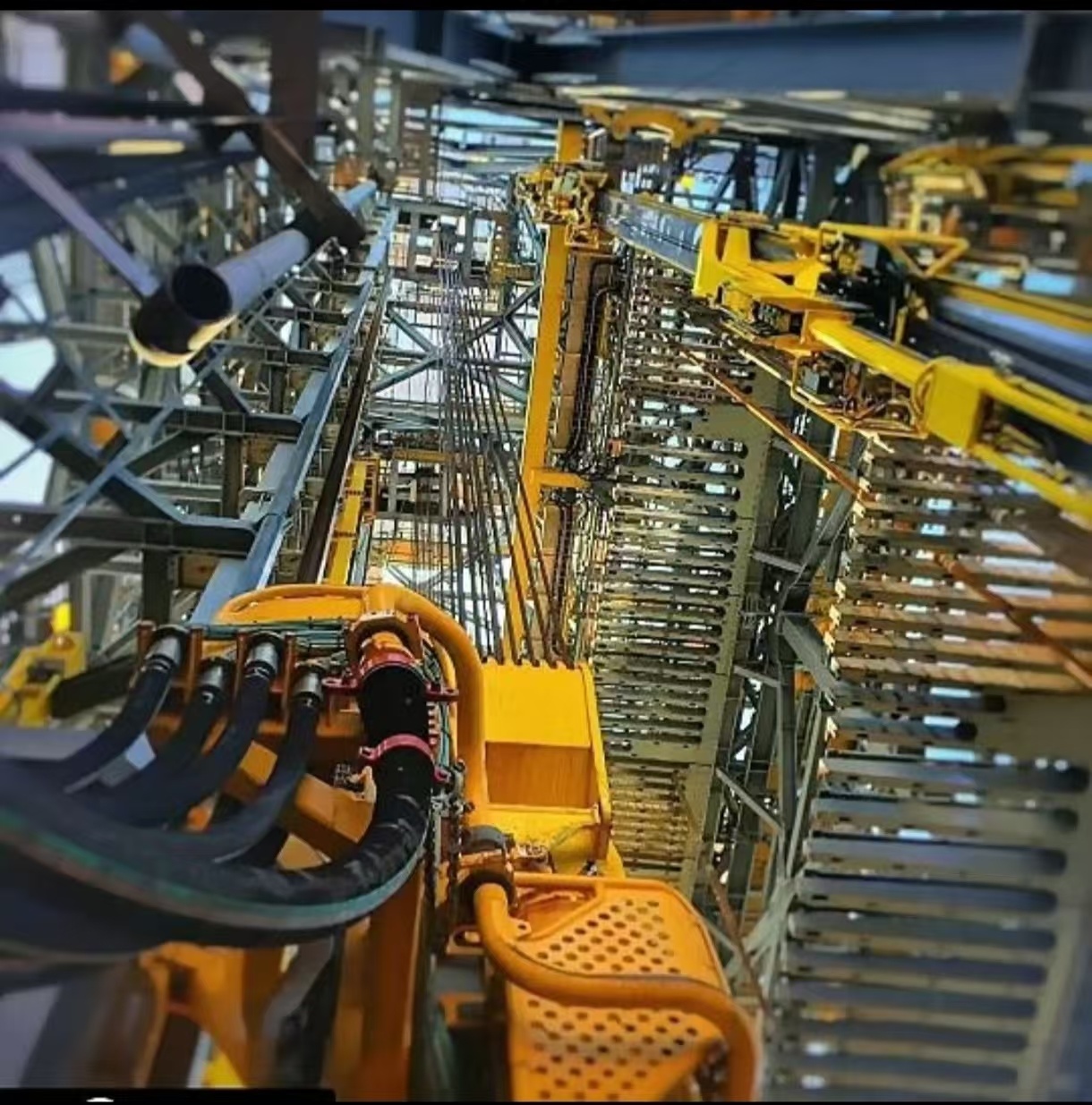

The petroleum industry relies on robust and reliable equipment to ensure safe and efficient operations. Among the critical components in fluid handling systems, **Hammer Unions** stand out as indispensable connectors for high-pressure pipelines. Known for their durability, quick assembly, and leak-resistant design, these fittings play a vital role in drilling, fracturing, and production processes.

What is a Hammer Union?

A Hammer Union (also known as a hammer lug union or hammer coupling) is a high-pressure pipe connector designed for quick installation and removal. Its distinctive hammer lugs allow workers to tighten or loosen the union using a hammer or wrench, making it ideal for field operations where speed and reliability are essential.

Key Features & Advantages

1.High-Pressure Resistance

- Rated for pressures up to 15,000 PSI and beyond, making them suitable for demanding oilfield applications.

- Constructed from forged steel, stainless steel, or alloy materials for enhanced strength and corrosion resistance.

2. Quick and Easy Installation

- Unlike flanged connections requiring multiple bolts, Hammer Unions can be hand-tightened and secured with a hammer, drastically reducing setup time.

3. Leak-Proof Sealing

- Equipped with metal-to-metal seals or elastomeric O-rings to prevent leaks in high-pressure fluid and gas transfer systems.

4. Versatility

- Used in drilling rigs, frac pumps, manifolds, and cementing equipment.

- Available in various sizes (1" to 4" and larger) and configurations (e.g., straight, elbow, tee).

Applications in the Petroleum Industry

- Hydraulic Fracturing (Fracking) – Connects high-pressure hoses and pumps.

- Drilling Rigs – Joins mud pumps, standpipes, and other critical components.

- Production & Refining – Facilitates safe fluid transfer in pipelines and processing units.

Industry Trends & Innovations

- Smart Hammer Unions – Some manufacturers now integrate IoT sensors to monitor pressure, temperature, and vibration in real time.

- Enhanced Materials – Advanced coatings and alloys improve resistance to H₂S corrosion and extreme temperatures.

- Standard Compliance – Modern designs adhere to API 6A, 16C, and ISO 9001 standards for safety and performance.

Choosing the Right Hammer Union

When selecting a Hammer Union, consider:

✔ Pressure Rating – Must match or exceed operational requirements.

✔ Material Compatibility – Stainless steel for corrosive environments, carbon steel for general use.

✔ Seal Type – Metal seals for high-temperature gas, elastomers for liquids.

Conclusion

Hammer Unions remain a cornerstone of efficient pipeline connections in the petroleum sector, offering unmatched convenience and reliability. As technology advances, we can expect even smarter, stronger, and more adaptable designs to meet the evolving needs of the industry.

For more details on Hammer Union specifications and applications, contact our sales team!

Key words: