Hydrocyclones: Efficient Solid-Liquid Separation Solutions

Apr 11,2025

Hydrocyclons are widely used in industry to separate solids and liquids. Its simple design and efficiency make it a key tool in several fields, including oil &gas drilling wastewater treatment, mining and agri-food. The working principle, advantages and application of hydrocyclone are discussed in this paper.

Hydrocyclones are versatile, high-efficiency separation devices used across industries to remove suspended solids from liquids.

1. How Hydrocyclones Work

Hydrocyclones use centrifugal force to separate particles based on size, density, and fluid dynamics. The separation process involves:

Tangential Feed Entry – The slurry enters under pressure, creating a high-speed rotational flow.

Centrifugal Separation – Heavier solids move outward to the wall and spiral downward.

Dual Exit Streams –Underflow (Spigot): Concentrated solids discharge at the bottom.

Overflow (Vortex Finder): Cleaned liquid exits from the top.

2. Hydrocyclone Working Principle

No Moving Parts,Low maintenance, high reliability, and long service life.

Compact Design,Saves space compared to sedimentation tanks or centrifuges.

High Efficiency,Effective for particles as fine as 5–10 microns (depending on design).

3. Industrial Applications

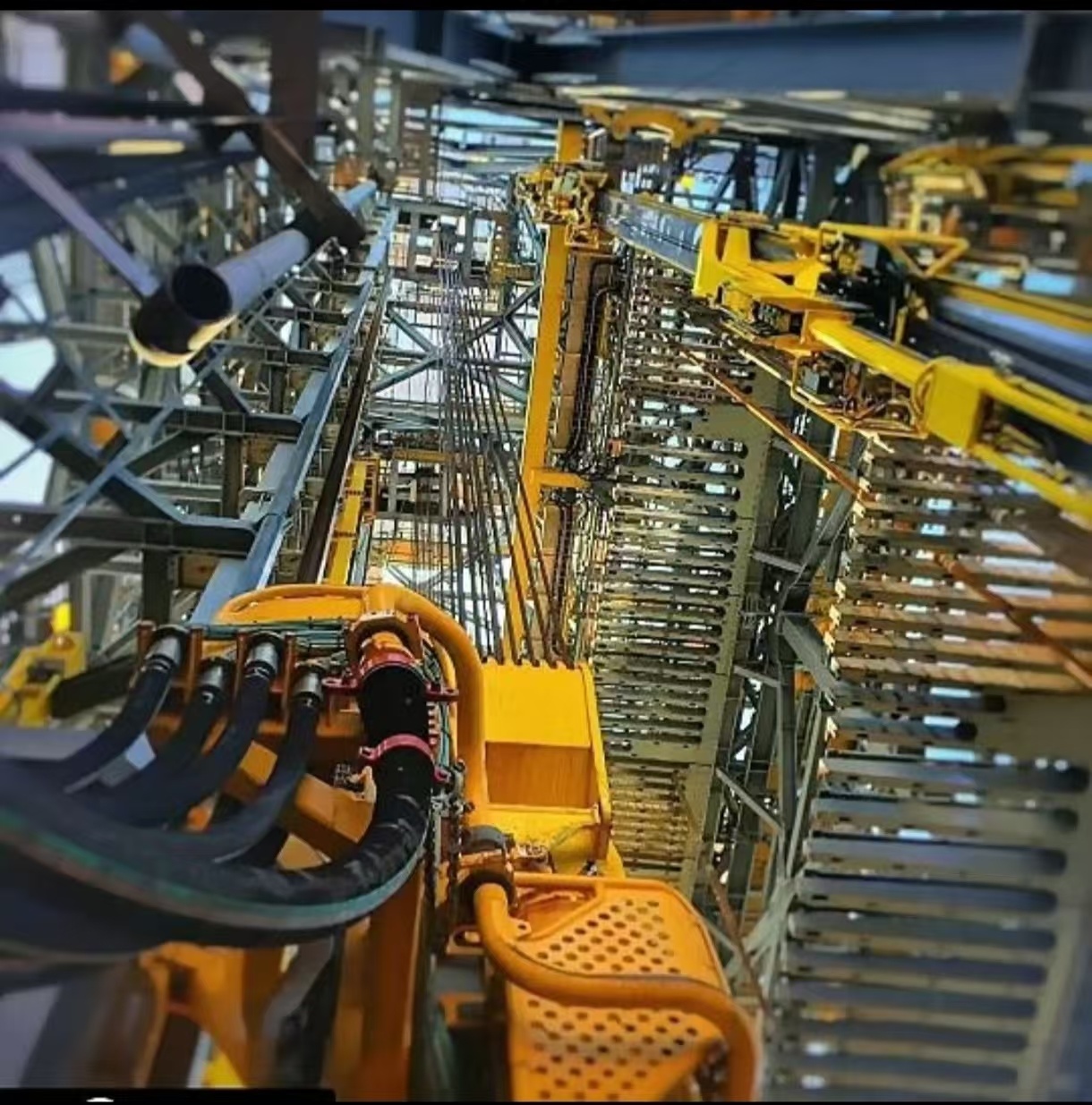

Oil & Gas Drilling Desanding: Removes abrasive particles from drilling mud to protect equipment.

Hydrocyclones are a proven, energy-efficient solution for solid-liquid separation across industries. By selecting the right design, materials, and operating parameters, operators can achieve high recovery rates, lower waste volumes, and reduced costs. For optimal results, pair hydrocyclones with downstream filters or centrifuges for ultra-fine polishing.

Need help sizing a hydrocyclone for your application? Consult with a separation specialist to match your process requirements!

Key words: