High-Wear Desilter Cone Elbow: Enhancing Mud Separation Efficiency

Apr 14,2025

This article introduces that the optimized cyclone elbow design reduces the downtime of drilling operations and the selection advantages

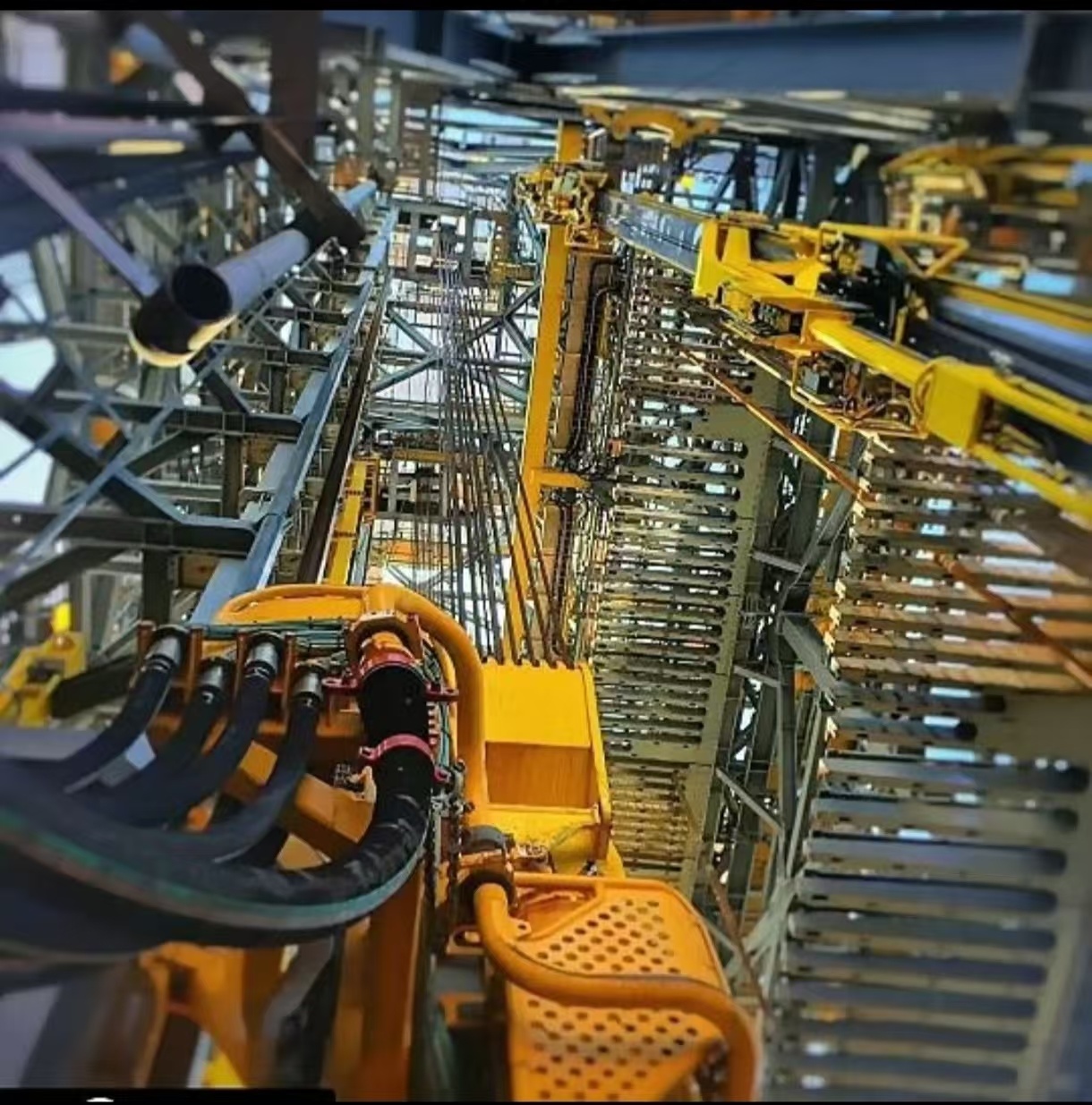

The desilter cone elbow is a critical component in solid control systems, primarily used in drilling fluid (mud) purification processes. It connects the hydrocyclone desilter cones to the manifold or downstream equipment, ensuring efficient flow direction and minimal pressure loss.

Key Features:

1. Material – Typically made from **wear-resistant materials** like high-chrome alloy, polyurethane, or ceramic to withstand abrasive drilling fluids.

2. Design – Engineered for smooth flow transition, reducing turbulence and erosion.

3. Function – Facilitates the separation of fine solids(15-30 microns) by directing slurry from desilter cones to the discharge line or shaker.

4. Compatibility – Fits standard 4″, 5″, or 6″ hydrocyclone cones, depending on the system configuration.

5. Durability – Resists corrosion and erosion, extending service life in harsh drilling environments.

Applications:

Oil & gas drilling rigs - HDD (Horizontal Directional Drilling) - Mining and industrial slurry separation.

Advantages:

✔ Optimizes desilter performance by maintaining proper flow dynamics.

✔ Reduces maintenance downtime with robust construction.

✔ Improves drilling fluid cleanliness by ensuring efficient fine solids removal.

This component is essential for maintaining high-efficiency solids control in modern drilling operations.

Key words:

PREVIOUS: