Anti slip pad for drilling platform

Jan 20,2025

Anti-slip pads are crucial components for drilling platforms, providing safety and stability in often challenging environments.

Anti-slip pads are crucial components for drilling platforms, providing safety and stability in often challenging environments. Here are some key aspects to consider regarding anti-slip pads for drilling platforms:

### Purpose and Functionality

1. **Safety**: Anti-slip pads help prevent slips and falls on the platform, which can lead to accidents and injuries.

2. **Stability**: They provide a stable footing for workers and equipment, especially in wet or oily conditions common in drilling operations.

3. **Equipment Protection**: Pads can also protect sensitive equipment from damage due to vibrations or shifting during drilling operations.

### Materials

1. **Rubber**: Commonly used due to its excellent grip and durability. It can withstand harsh environmental conditions.

2. **Polyurethane**: Offers good slip resistance and is resistant to oils and chemicals.

3. **Composite Materials**: These can be engineered to provide specific properties such as enhanced grip or resistance to environmental factors.

### Design Features

1. **Textured Surface**: A textured or patterned surface enhances grip, reducing the likelihood of slips.

2. **Thickness and Density**: Thicker pads can absorb more shock and provide better cushioning, while denser materials offer greater durability.

3. **Interlocking Designs**: Some pads can interlock, providing a seamless surface that minimizes gaps where liquids can accumulate.

### Installation and Maintenance

1. **Easy Installation**: Pads should be designed for easy installation and removal for maintenance or replacement.

2. **Regular Inspection**: Regular checks should be conducted to ensure that the pads are in good condition and replace them as necessary to maintain safety standards.

### Regulatory Compliance

1. **Standards**: Ensure that the anti-slip pads meet relevant safety and industry standards, such as those set by OSHA or other local regulatory bodies.

2. **Certification**: Look for pads that are certified for slip resistance and durability in industrial environments.

### Applications

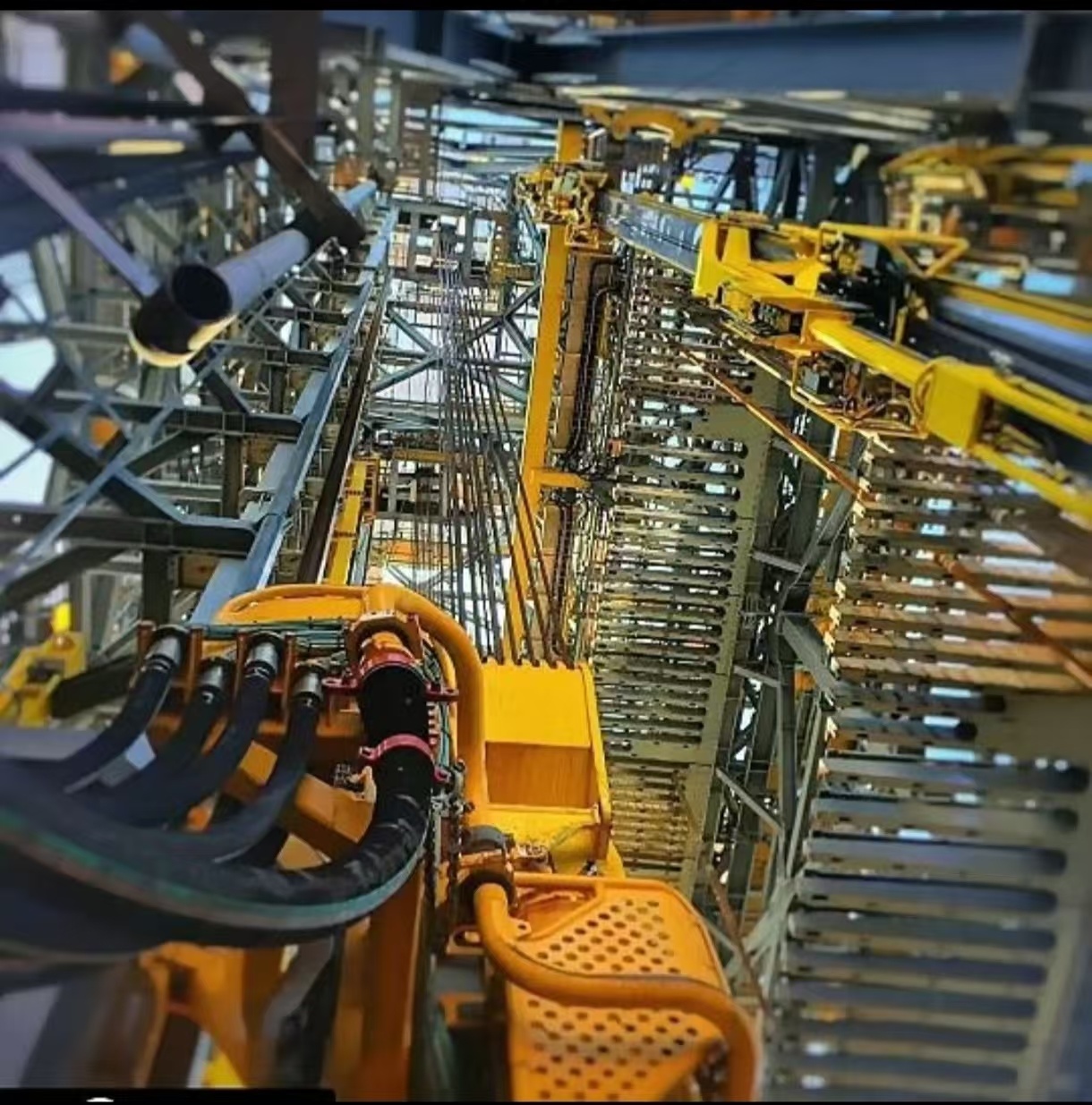

1. **Drilling Rigs**: Used on the main deck and work areas to provide a safe working environment for personnel.

2. **Workstations**: Anti-slip pads can be placed in areas where heavy equipment is operated or where workers frequently move.

### Custom Solutions

1. **Tailored Products**: Some manufacturers offer custom solutions to meet specific needs or dimensions of drilling platforms.

2. **Branding**: Pads can sometimes be customized with company branding or specific colors for easy identification.

When selecting anti-slip pads for a drilling platform, consider the specific operational conditions, the type of materials being used, and the safety requirements of your particular site. Always consult with suppliers or experts in industrial safety to choose the best options for your needs.

Key words: