The Importance of Hydraulic Pipes in Modern Machinery

Jan 20,2025

In today's fast-paced industrial environment, the efficiency and reliability of machinery are paramount. One of the key components that contribute to the functionality of various machines is hydraulic pipes. These pipes are integral to hydraulic systems, which are widely used across numerous sectors, including manufacturing, construction, and transportation. This article explores the significance of hydraulic pipes in modern machinery, focusing on their functionality, advantages, and the challenges they face.

Introduction

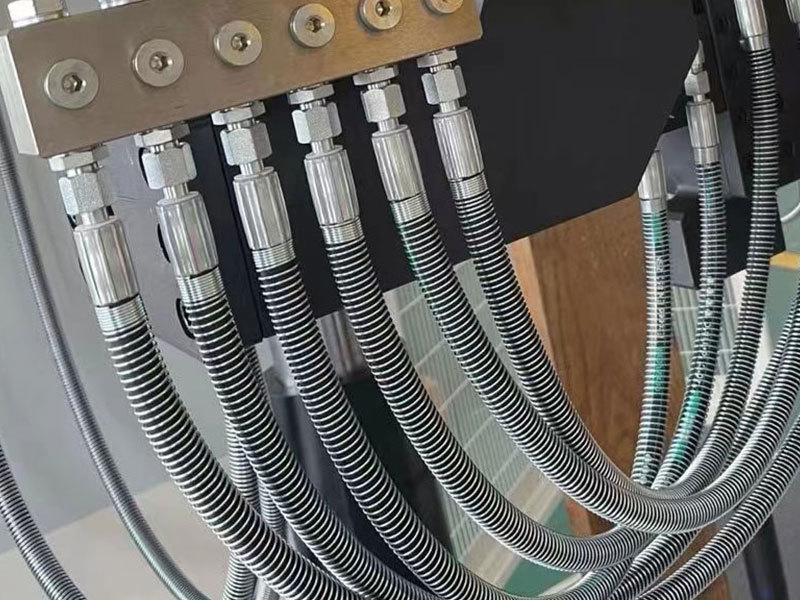

Hydraulic pipes are designed to transport hydraulic fluid under high pressure, which is essential for the operation of hydraulic systems. These systems use pressurized fluid to generate force and motion, enabling machines to perform tasks that would be impossible with mechanical systems alone. For instance, hydraulic pipes are critical in excavators, forklifts, and aircraft, where they facilitate the movement of heavy loads and enhance precision. The efficiency of hydraulic systems largely depends on the quality and integrity of the pipes used, making them a vital component in modern machinery.

Benefits

*One of the primary advantages of hydraulic systems, and consequently hydraulic pipes, is their ability to transmit power efficiently. Unlike mechanical systems that rely on gears and levers, hydraulic systems can generate a significant amount of force with relatively small components. This efficiency is particularly beneficial in applications where space and weight are constraints, such as in aerospace engineering. Hydraulic pipes allow for a compact design, enabling manufacturers to create lightweight yet powerful machinery.

*Another notable benefit of hydraulic pipes is their versatility. They can be used in a wide range of applications, from heavy construction equipment to delicate medical devices. The adaptability of hydraulic systems means that they can be tailored to meet specific requirements, whether it is for lifting heavy loads or controlling intricate movements. This versatility makes hydraulic pipes indispensable in various industries, providing solutions that enhance productivity and performance.

Moreover, hydraulic systems can operate in harsh environments where traditional mechanical systems might fail. Hydraulic pipes are typically made from durable materials that can withstand extreme temperatures, pressures, and corrosive substances. This resilience ensures that hydraulic systems remain functional even in challenging conditions, such as underwater operations or in chemical plants. The ability to maintain performance under such circumstances underscores the importance of hydraulic pipes in modern machinery.

However, despite their numerous advantages, hydraulic pipes are not without challenges. One of the primary concerns is the risk of leaks. Hydraulic fluid leaks can lead to system failures, environmental hazards, and safety risks. Regular maintenance and inspection of hydraulic pipes are crucial to identify potential issues before they escalate. Manufacturers must also adhere to strict quality standards when producing hydraulic pipes to ensure their reliability and longevity.

Another challenge facing hydraulic pipes is the potential for wear and tear over time. Factors such as temperature fluctuations, pressure changes, and exposure to chemicals can degrade the material properties of hydraulic pipes. To combat this issue, advancements in technology have led to the development of more durable materials and coatings that enhance the lifespan of hydraulic pipes. Continuous innovation in this field is essential to meet the evolving demands of modern machinery.

Conclusion

hydraulic pipes play a vital role in the functionality and efficiency of modern machinery. Their ability to transmit power efficiently, versatility in applications, and resilience in harsh environments make them indispensable in various industries. However, challenges such as leaks and wear must be addressed through regular maintenance and technological advancements. As industries continue to evolve and demand more from their machinery, the importance of hydraulic pipes will only grow, solidifying their place as a cornerstone of modern engineering.

Key words: