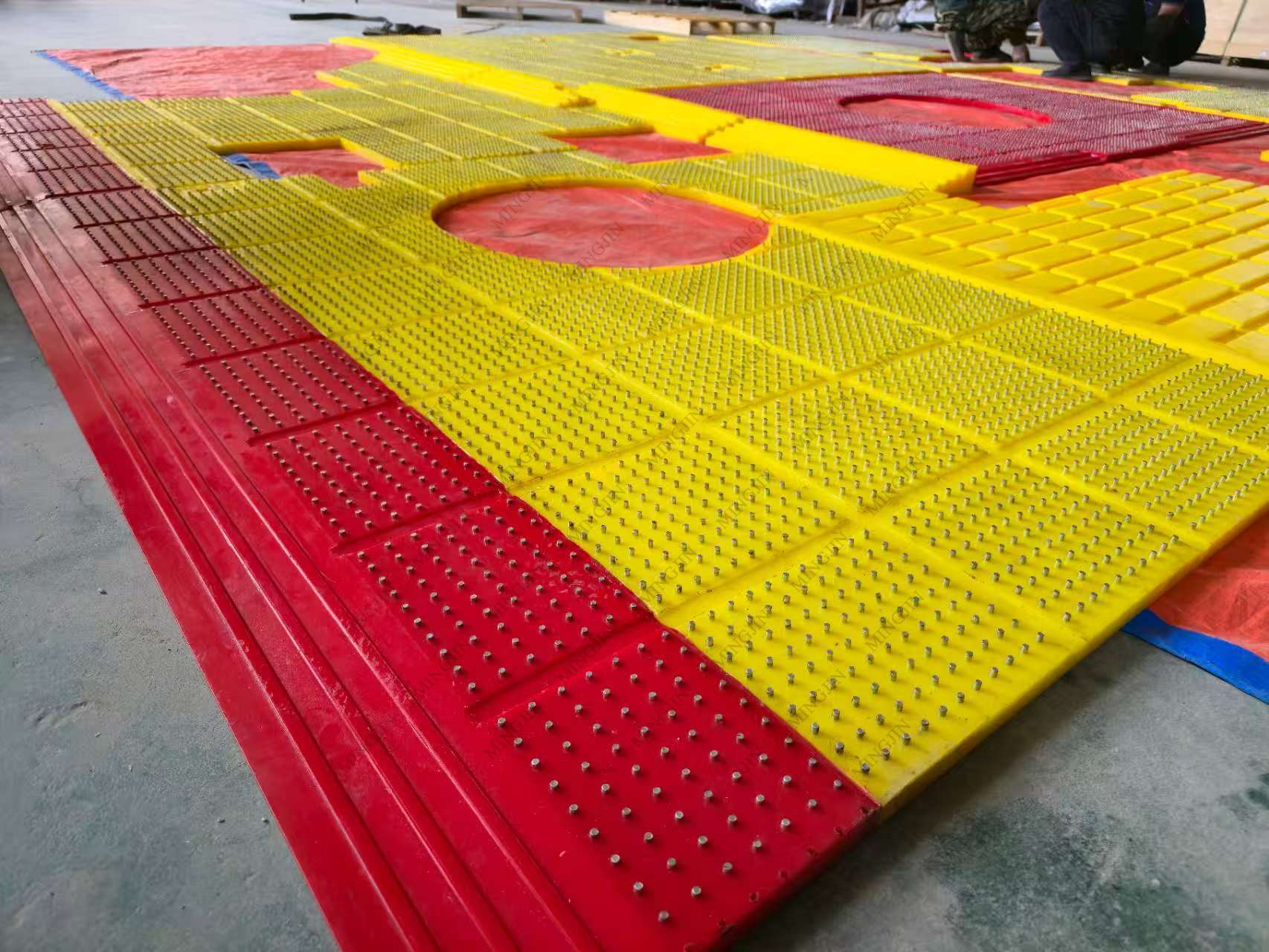

Tailored anti-slip mats for drilling platforms

Jun 25,2025

Tailored anti-slip mats for drilling platforms are **critical safety components** designed to withstand the extreme, hazardous environments of offshore and onshore drilling operations.

Tailored anti-slip mats for drilling platforms are **critical safety components** designed to withstand the extreme, hazardous environments of offshore and onshore drilling operations. Here’s a breakdown of key features, benefits, and considerations:

Core Requirements:

1. Extreme Slip Resistance:

- Materials:** polyurethane with aggressive diamond/stud patterns.

- Performance: Must maintain grip when soaked in oil, grease, seawater, mud, or chemicals .

2. Durability & Resistance:

- Corrosion: Saltwater-resistant; non-corroding materials (e.g., stainless steel fasteners).

- Chemicals: Resistant to H₂S, drilling fluids, solvents, and hydraulic oils.

- Temperature: Withstands -30°C to +80°C.

- Abrasion: Heavy-duty construction to endure boots, equipment, and dropped tools.

3. Customization:

- Precise Fit: Cut to match deck layouts, stairs, walkways, pipe racks, and machinery footprints.

- Holes/Features: Custom-cut for drains, hatches, bollards, or cable routing.

- Thickness: 15mm–50mm for high-impact areas (e.g., drill floor).

4. Safety & Compliance:

- Fire Resistance: Meets SOLAS/IMO FTP Code Part 2 (low flame spread, minimal smoke/toxicity).

- Anti-static: Prevents sparks in explosive atmospheres (ATEX/IECEx zones).

- Edge Safety:Beveled edges or ramped designs to prevent tripping.

5. Installation & Maintenance:

- Secure Fixing: Welded studs, adhesive, or mechanical fasteners (no curling edges).

- Easy Cleaning: Drainage channels; hose-down compatible.

- **Longevity:** 5–10+ years with proper maintenance.

Key Benefits:

- Fall Prevention:** Reduces slips/trips—major causes of offshore injuries.

- Fatigue Reduction:** Cushions legs during long shifts on steel decks.

- Asset Protection:** Shields deck coatings from abrasion/corrosion.

- Compliance: Meets OSHA, ISO 9001, DNV GL, and platform-specific safety standards.

Top Suppliers (Specialized):

1. mingjin (Hengshui Mingjin Rubber And Plastic Products Co., Ltd): Heavy-duty polyurethane mats with oil resistance.

2. Eco-Rubber: Custom-cut recycled polyurethane mats (eco-friendly option).

3. Mats Inc.: Chemical/fire-resistant mats for energy sector.

4. Anchor Rubber: Offshore-grade mats with non-slip textures.

5. Local Fabricators: Often provide site surveys for perfect fit

Cost Considerations:

- Price Range: $50–$500 per m² (based on thickness, material, certification).

- ROI: Justified by reduced downtime, injury costs, and extended deck life.

Implementation Tips:

- Site Survey: Use 3D scans or templates for complex layouts.

- Prioritize Zones: Focus on drill floor, stairs, crane operating areas, and slick pathways.

- Certification: Ensure mats meet **NORSOK R-002** (offshore standards) and **DNVGL-RU-OU-0502

Conclusion:

Custom anti-slip mats are non-negotiable for drilling platform safety. Invest in tailored, high-specification mats** that match the unique hazards of your operation—avoid generic solutions. Partner with suppliers experienced in offshore energy to ensure compliance and durability.

> 🛠️ **Pro Tip:** Combine mats with anti-slip tape on rails/stairs and enforce "clean-as-you-go" policies to maximize effectiveness.

Key words: