Enhancing Safety and Efficiency: The Role of Drilling Platform Anti-Slip Mats

Jul 31,2025

In the demanding environments of drilling platforms, safety is paramount. One essential component that contributes to a safer workplace is the drilling platform anti-slip mat. These mats are specifically designed to provide traction and reduce the risk of slips and falls in areas where workers are frequently moving equipment or handling materials. The importance of these mats in maintaining a secu

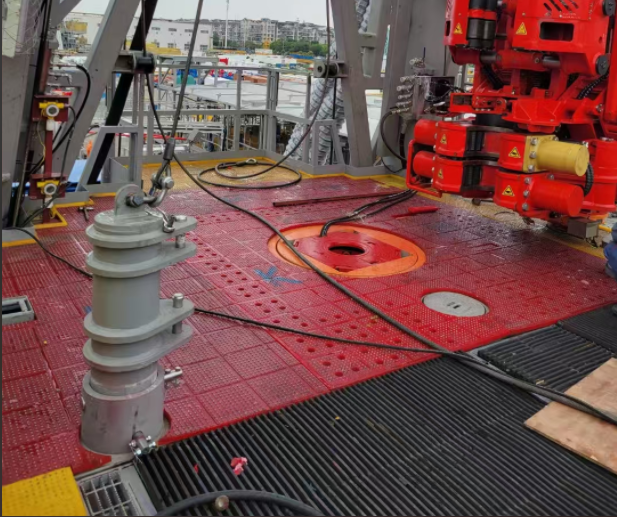

In the demanding environments of drilling platforms, safety is paramount. One essential component that contributes to a safer workplace is the drilling platform anti-slip mat. These mats are specifically designed to provide traction and reduce the risk of slips and falls in areas where workers are frequently moving equipment or handling materials. The importance of these mats in maintaining a secure working environment cannot be overstated.

Drilling platforms are often subject to harsh conditions, including exposure to chemicals, moisture, and heavy machinery. Anti-slip mats serve as a critical line of defense against accidents, helping to prevent injuries that can lead to lost productivity and increased operational costs. These mats are typically made from durable materials, such as rubber or PVC, which not only provide excellent grip but also withstand the rigors of the drilling environment.

The design of anti-slip mats features textured surfaces that enhance grip, allowing workers to maintain better footing even in wet or oily conditions. This is especially crucial in the chemical industry, where spills can occur unexpectedly. By incorporating anti-slip mats into the layout of a drilling platform, companies can significantly reduce the likelihood of accidents and create a safer workplace for their employees.

In addition to their safety benefits, drilling platform anti-slip mats also contribute to operational efficiency. These mats can help define work zones, making it easier for employees to navigate busy areas. By clearly marking safe walking paths, they facilitate smoother operations, ultimately leading to better productivity. Furthermore, the use of these mats can reduce wear and tear on the flooring of the platform, extending its lifespan and minimizing maintenance costs.

To maximize the effectiveness of anti-slip mats, regular maintenance is essential. It is advisable to clean these mats frequently to remove any debris, oil, or chemical residues that may accumulate over time. This not only helps maintain their anti-slip properties but also ensures they remain in good condition for prolonged use. Additionally, periodic inspections should be conducted to identify any signs of wear and tear, allowing for timely replacements when necessary.

In summary, drilling platform anti-slip mats play a vital role in enhancing safety and efficiency on drilling sites. Their durable construction and effective design help prevent accidents, improve worker confidence, and contribute to overall operational effectiveness. By prioritizing the integration of these mats into your safety protocols, you can create a more secure working environment that protects your most valuable asset—your workforce.

Key words: