Contact

WhatsApp:

Add:

Jingcounty,Hengshui,Hebei,China

4inch Desliter hydro cyclone

- 产品描述

-

Product Description

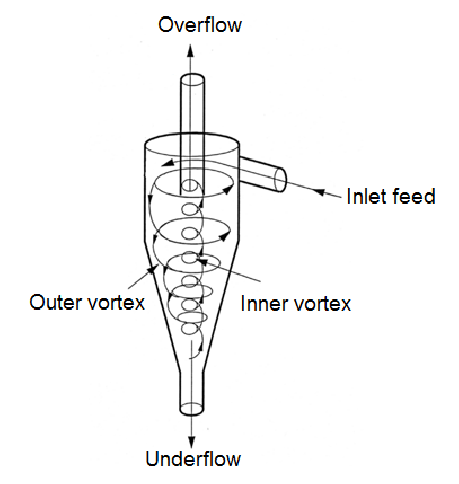

Hydrocyclones, commonly referred to as cyclone separators, are essential devices in the field of drilling fluid management. They play a crucial role in the separation process by effectively removing unwanted particles from the drilling fluid. Among the various types of hydrocyclones, two notable categories are the hydrocyclone desander, which typically features a 10-inch cone, and the hydrocyclone desilter, characterized by a smaller 4-inch cone. These specialized hydrocyclones are designed specifically to separate sand and silt from the drilling fluid, ensuring that the fluid remains clean and efficient for use in drilling operations. To facilitate the operation of these hydrocyclones, a centrifugal pump is employed. This pump is responsible for transferring the drilling fluids from the mud tank into the hydrocyclones. The efficient functioning of the centrifugal pump is vital, as it ensures a steady flow of drilling fluid, allowing the hydrocyclones to perform their separation tasks effectively. By utilizing this combination of hydrocyclones and centrifugal pumps, the drilling industry can maintain optimal fluid properties, enhance drilling performance, and minimize downtime caused by the presence of unwanted solid materials.

A hydrocyclone has two exits on the axis:

The smaller on the bottom (underflow or reject).

The larger at the top (overflow or accept).

The underflow is generally the denser or thicker fraction, while the overflow is the lighter or more fluid fraction.

The operational efficiency of hydrocyclones, particularly the 4-inch desilter, is significantly influenced by various factors, including the inlet pressure, feed rate, and the viscosity of the drilling fluid. Optimal performance is achieved when these parameters are carefully monitored and adjusted according to the specific conditions of the drilling site. For instance, maintaining an appropriate inlet pressure ensures that the hydrocyclone can effectively generate the necessary centrifugal force for particle separation. Furthermore, the feed rate must be balanced to prevent overloading, which can lead to reduced separation efficiency and increased wear on the hydrocyclone components. The viscosity of the drilling fluid also plays a crucial role; higher viscosity fluids may hinder the flow through the hydrocyclone, resulting in less effective separation. Therefore, operators must regularly assess and adjust these parameters to maximize the performance of the hydrocyclone desilter. Additionally, routine maintenance and inspections are essential to identify wear and tear on the hydrocyclone and its associated components, ensuring that they operate at peak efficiency. By optimizing these operational factors, drilling companies can significantly improve their drilling fluid management processes, leading to enhanced drilling efficiency, reduced operational costs, and a lower environmental impact due to better handling of solid waste. In conclusion, the careful integration of hydrocyclones, particularly the 4-inch desilter, with effective operational strategies is vital for achieving success in modern drilling operations.

Related Products

hydrocyclone desilter hydrocyclone 4inch with elbow

5inch hydrocyclone for fine particle separation

4 inch Nov hydrocyclone desilter cone with elbow